MAKING > NATURAL STONE

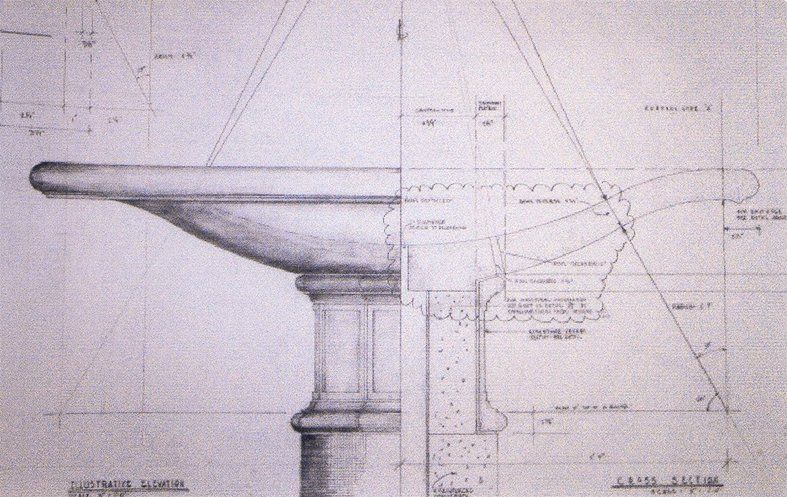

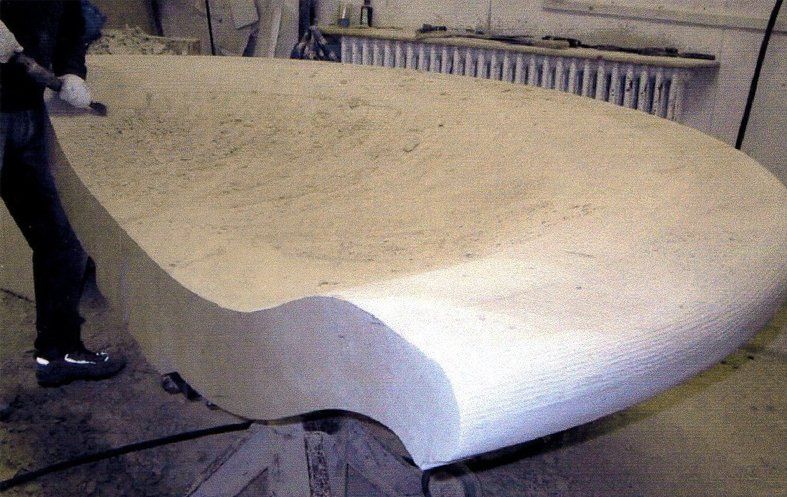

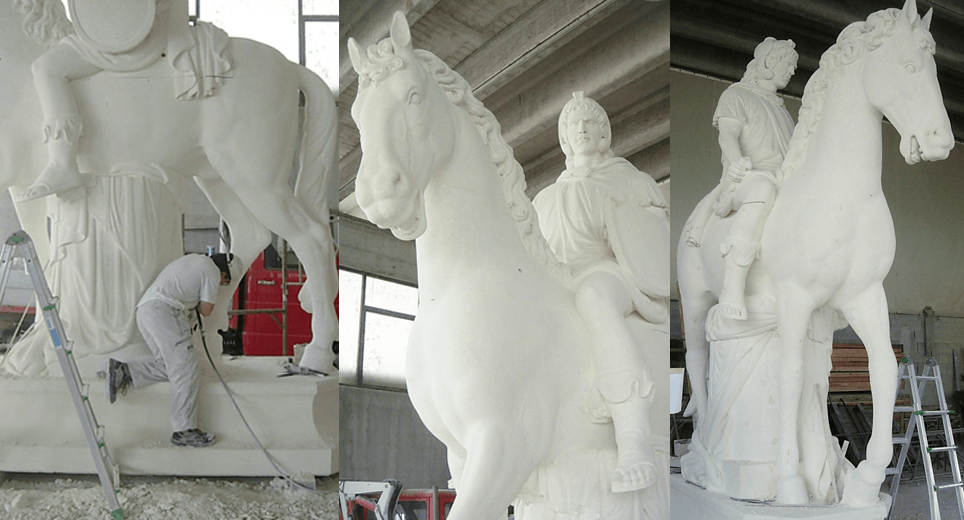

Alexander Widmann, Gertrud Mitterstieler-Widmann, natural stone and bronze work, Algund, South Tyrol. Own collections in natural stone and bronze and commissioned work: fountains, wall fountains, boulder fountains, sculptures, statues, figures, chimney cladding, tombstones, plant vessels, vases, benches and tables, stone in the building, building elements, balcony railings, vaults, entrance borders, fountain figures, garden figures, Small bronze figures, bronze relief, stone relief.

THE QUARRY

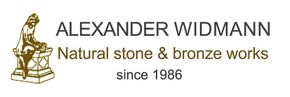

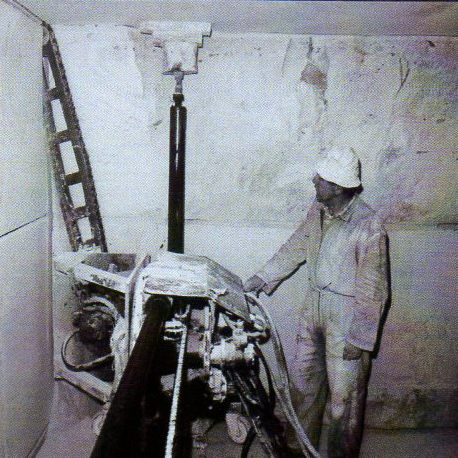

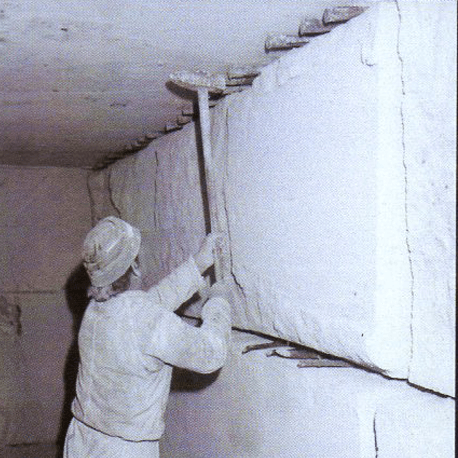

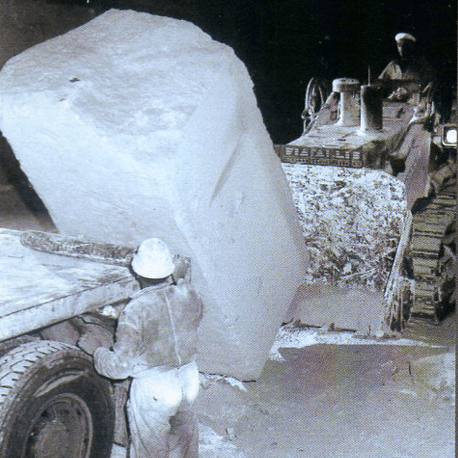

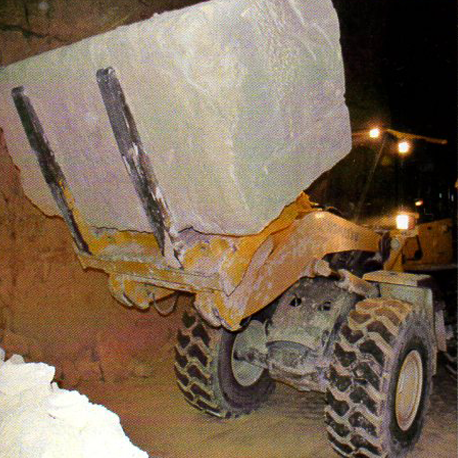

The extraction of natural stones takes place “normally” in the quarry. A distinction can be made here between the extraction in open quarries (slope break, boiler break, etc.) and the extraction in underground mining (gallery break, mine, pit).

The less unusable soil or rock (overburden) that has to be removed, the more profitable the extraction.

Underground mining is more complex, it is usually only worthwhile for rocks that cannot be extracted otherwise. These are often certain marbles, including slate, since unweathered slate deposits can often only be found deep in the ground.

Today the diamond wire saw is mostly used to cut, even with hard stones, very soft stones, such as travertine, are often still mined with cutting machines (a type of chainsaw). Natural stone is cut into rough blocks and then transported on for processing.